Join our founder Jo England, to learn about the fascinating world of Jute. Jo recently visited the incredible century-old facility Kankaria Jute Mills in Kolkata.

The jute processing factory has been a beacon of local empowerment, nurturing the livelihoods of 5000 workers. Join us on a journey of a heritage industry, where every thread tells a story, and every process is a testament to the commitment to quality.

Jute, often hailed as the "Golden Fibre," stands as the world's second-largest textile after cotton. Thriving in the monsoon, jute is a versatile gift from nature, offering strength, affordability, and sustainability, making it the 'Fibre for the future.' Used for bagging grain, rice and shopping bags, let's delve into the heart of the process with these stunning images of a private tour.

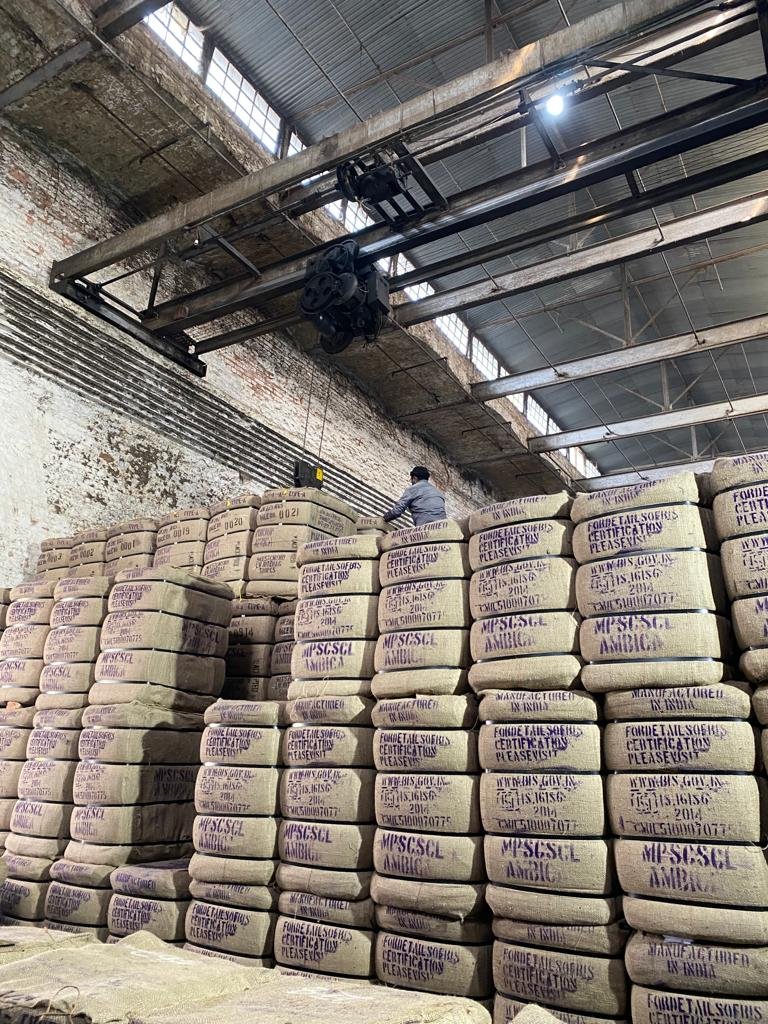

The raw Jute arrives by truck at at the facility from the villages and farmers.

Selection & Grading: Every step is meticulously crafted by hand. Jute is delicately split into uniform parts, ensuring seamless feeding into the next process. Waste is not a concept here; every fibre finds its purpose, contributing to the finesse of our final products.

Raw Jute Piling After Spreader: Patience is key as the jute fibres rest, allowing moisture to penetrate and soften, preparing them for the next phase of transformation.

Carding (2 Processes): Here, jute fibres undergo a refining process, shedding impurities and forming ribbons of sliver, setting the stage for quality yarn production.

Drawing (3 Processes): Through careful stretching and combing, sliver weight is reduced, and fibres are aligned, ensuring uniformity and strength in our yarn.

Spinning: The heartbeat of our mills, spinning transforms slivers into yarn, infusing them with strength and durability.

Winding & Beaming: Yarns find their form, either as spools or cops, ready to weave stories into fabrics. Beams are meticulously prepared, ensuring efficiency and quality in every weave.

Weaving: Warp meets weft, and fabrics come to life on our looms, weaving together threads of tradition and innovation.

Cut, Stitch & Print: From fabric to bags, our craftsmen cut, stitch, and print with precision, turning raw materials into functional and fashionable products.

Bale Packing & Dispatch: Bundled with care, our products are packed and dispatched, ready to embark on new journeys, carrying with them the legacy of our craftsmanship.

For more information contact us @tribedubai